CNC Router duplication has been around a long time. Early machines used

stiluses to follow the shape of a pattern or master, while on the other end of

the machines, routers did the carving. In a similar but computerized fashion,

CNC routers are also capable of duplicating existing carvings and furniture

parts. A digital “touch” probe is first used in the CNC to sense the surface of

the object, while the probe’s accompanying software creates a digital image of

the part.

The digital image is then converted to a 3D model and used to program CNC

routing paths for a replica. To test the capabilities of this technique, I hand

carved a traditional scallop shell measuring about 4″ x 4″ to use as my

original. My test revealed that a CNC digital probe is quite capable of

accurately recording the shape of an object, with one exception; due to its

ballshaped tip, the probe rounds off the inside corners of fi ne details such

as the veins on this shell. A little bit of hand carving easily adds the missing

details. The three carvings in the photo below are duplicates of my original

(photo above). Watch the digital probe in action at

AmericanWooodworker.com/CNC.

Step 1

Set the scanning parameters. The

software control panel is used to set the

size of the scanning area, the precision or

resolution of the scanning action, and the

speed of the scan. The Scan Limits of X and Y

represent the width and length of the scan

area, while the Z Scan Limit represents the

range the probe travels vertically. The Step

Sizes are the X and Y distances the probe

moves between measurements. The Scan

Velocity controls the speed of the probe as

it moves across the part’s surface. The Part

Coordinates show the location of the probe

during operation. I used the Shark CNC Pro

Plus to scan the shell for this article, but

most CNCs, including the CarveWright and

Shopbot, are capable of probe scanning.

Step 2

Scan the part. I set parameters for

this shell

carving as shown in Step 1. The X and Y

scanning limits are penciled on the backer

board. The Z limit was set at 1” to provide

sufficient vertical travel for the carving’s 5/8”

thickness. The step sizes of .005” for this shell

equals 800 passes across the shell for a total

of 680,000 steps, or measurement points, and

took about 12 hours. ( I ran this overnight). The

Shark CNC probe has a .075” dia. wear-resistant

industrial ruby tip, so certain details such as the

fine veins on this shell were not fully captured;

but the remainder of the surface was captured

with surprising accuracy. A larger step setting

can be used on objects with less detail, such

as a chair seat. Doubling the step size reduces

scanning time by a factor of four.

Step 3

Adjust the digital image. The

scanning creates an .stl file, which is a

common file type used in 3D modeling.

The scanned area surrounding the shell is

not needed and is removed at this time.

Step 4

Create the 3D model. The .stl file is

converted to a 3D model with CNC

design software such as Aspire by

Vectric. I also used Aspire to increase

the thickness of the shell’s base to 1/4”.

Step 5

Smooth the surface. If needed, the

design software can also be used to

smooth the surface of the model. My

scan was fine enough so I only needed

to remove a couple scratches.

Step 6

Remove the background.

I removed the background to get

the waste material out of the way

in order to make it easier to add the

final hand carved details in Step 10. I

programmed the toolpath for the 3/4”

straight bit at a .1” depth-of-cut per

pass and a stepover (pass width) of .2”.

The tool path was also programmed

to leave the shell profile .125” oversize.

Removing the background for the

three shells took about 30 minutes. The

board started out .875 (7/8” ) thick and

the routed background is .25” thick.

The shell will have a final thickness

of .75”.

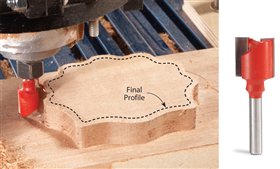

Step 7

Rout the final profile and tabs.

The final profile is made using a

1/4” straight bit that cuts all the way

through the material. Tabs are left to

hold the shell in place. These tabs can

also seen in bottom photo on page 15.

A piece of plywood underneath

protects the metal machine bed from

damage. I programmed the toolpath

for the 1/4” straight bit for .125” depth

passes. The profile and tab routing of

the three shells took about 8 minutes.

Step 8

Rough rout the shape.

To accomplish the rough routing I

used a 1/4” ballnose bit programmed

to a .1” depth of cut and .1” step over

(pass width). This roughing phase

removes the majority of the material.

The amount of material left by the

rough pass is adjustable, with .02” being

common for a carving such as this shell.

Leaving this small amount allows the

final pass to be completed in one pass,

saving time and wear on the finishing

bit. The rough routing of the three

shells took about 60 minutes.

Step 9

Rout the final pass.

The final carving is done with a

specialty .0625” (1/16”) ballnose bit

(available at BeckwithDecor.com). I

programmed this bit to make .01” wide

(1/100”) passes. The tiny tip of this bit

is capable of recreating a considerable

amount of detail, and leaves a surface

that only requires a light sanding with

220 grit sand paper to make it ready for

finishing. The final routing of the three

shells took about 70 minutes.

Step 10

Detail by hand as needed.

Complete the carving with some touchup

hand carving of the veins and finish

sanding. There are CNC operations

where the goal is to create a part that

requires no additional hand work—this

application is not one of them. A CNC

is a tool capable of many things, but a

realistic expectation of what it can do

is also important. In the case of these

shells, I accepted the fact that I would

need to do some hand detailing to

achieve the results I wanted, similar to

scraping or sanding a board after

jointing and planning.

Step 11

Make the boxes. After making the

shells, the box shape is simple to

program using the profile of the shell

as a pattern. It took about 150 minutes

to rout the 3 boxes on the CNC using a

1/4” up-spiral bit. They were cut out of

1-1/2” material.

Project Time Card

CNC the lids: 55

minutes each

CNC the boxes: 50

minutes each

Set up and material prep: 15

minutes each

Detailing and sanding: 45

minutes each

Staining and finishing: 20

minutes each

Total time: 3

hours 30 minutes each

I spent 5 hours 15 minutes (total for

all three)

doing something else while

the CNC Router ran.