PCBs are

normally etched using solutions such as ‘clear etchant’ or ‘ferric chloride’.

These are dangerous chemicals and if contact is made with the skin or

especially the eyes, the medical consequences can be serious. Photo-resist

board is used with etchants and other solutions to produce PCBs. The waste

produced when using ferric chloride or clear etchant on photo-resist board must

be handled with care and should not just be poured straight down the sink,

especially in large amounts.

Many people, especially in schools, prefer to use software such as Real PCB to export PCB designs so that they can be cut to shape on a CNC router. The router below is similar in size to existing machines that are used to manufacture PCBs. They are safe to use because the waste produced can quite simply be brushed up and thrown away in a normal dust bin. This is because copper clad board is used instead of photo-resist board. Chemicals are not needed.

It must be

remembered that manufacturing PCBs with a router is much slower than etching,

although this depends on the size of the PCB. A CNC router is generally used to

shape/cut one PCB at a time, whilst an etchant tank can hold several PCBs at

once.

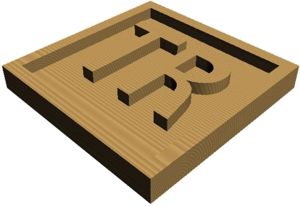

The diagram above shows a piece of copper clad board that has been cut to shape (’milled’) on a CNC router, producing a printed circuit board.

The diagram above shows a piece of copper clad board that has been cut to shape (’milled’) on a CNC router, producing a printed circuit board.

Printed Circuit

Boards produced through the use software such as Real PCB, a CNC router. and

copper clad board is expensive but the most environmentally friendly method.

Chemicals are not used. This is regarded as the safest method of manufacturing

PCBs.

Printed Circuit

Boards produced through the use of a UV box, developing chemicals and etchants

is the cheapest method of manufacture but the least environmentally friendly.

Safety must be taken seriously when using this method manufacturing.

The waste produced

through the manufacture of PCBs on an industrial scale, through the use of

etchants and chlorides, has been blamed for serious pollution in the North Sea

(North coast of England and Scotland). Within the last 15 years these

pollutants have been blamed for the decline in fishing stocks and in

particular, the decline of the seal / dolphin populations.

Below are some

of the warning symbols that appear on etchants and ferric chloride solutions.

They are present to warn the user of their potential danger if mishandled.

QUESTIONS:

1. Describe the difference in the way PCBs are manufactured on a CNC machine and through etchants / ferric chlorides.

2. Why should etchants and solutions such as ferric chloride be handle with great care?

1. Describe the difference in the way PCBs are manufactured on a CNC machine and through etchants / ferric chlorides.

2. Why should etchants and solutions such as ferric chloride be handle with great care?